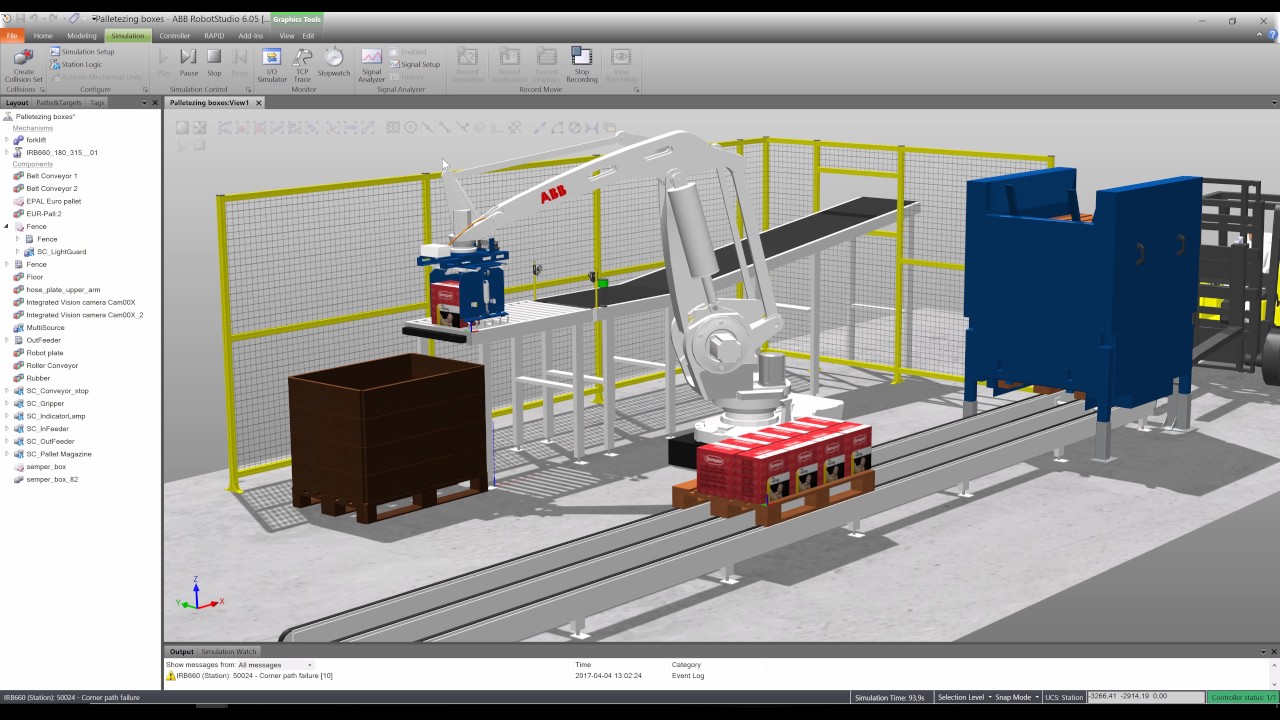

Also check that Access level is set to “All”. Finally, pick the desired bit number for the signal in the Device Mapping option. In order to create a signal, choose “Digital Input” (input bit) or “Digital Output” (output bit) as Type of the Signal and pick the previously created device in Assigned to Device. In this screen, the individual bits and the group bytes will be created, including the mapping between them. Then, click OK to create the device.Īt this point, the proper I/O signals can now be created by right-clicking on the Signal option, below EtherNet/IP Device. The values that must be changed are the Simulated option, set to True, and finally the Output Size and Input Size in bytes, which are the maximum number of bytes used. In the next screen, let’s pick at the top the template called ABB Local I/O Device, which will include some defaults. Finally, right-click the EtherNet/IP Device option shown in the new screen to create a new one. In the Controller tab, double-click in the Configuration node located on the left navigation bar and then click on I/O System. To do so, a virtual device must be previously created, so the different bit signals can be mapped to bytes. Next, let’s create the different I/O variables. The following steps are only needed for the I/O signals. The tool is built on the ABB Virtual Controller, an exact copy of the real. Robot axis data is automatically exchanged. ABBs simulation and offline programming software, RobotStudio, allows robot programming to be done on a PC in the office without shutting down production, this allows you to perform tasks such as training, programming, and optimization without disturbing the production. Tutorial 5 - Electric and pneumatic circuits

0 kommentar(er)

0 kommentar(er)